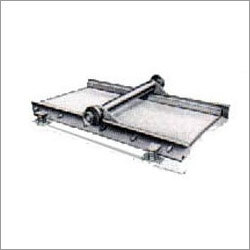

लिक्विड स्क्रीन सेपरेटर

उत्पाद विवरण:

- पावर सोर्स Electric

- सतह की फ़िनिश Polished

- विशेषताएँ Easy to clean, High separation efficiency, Low vibration

- मटेरियल Stainless Steel

- टाइप करें

- स्ट्रक्चर

- बेल्ट कन्वेयर

- अधिक देखने के लिए क्लिक करें

X

लिक्विड स्क्रीन सेपरेटर मूल्य और मात्रा

- 1

- टुकड़ा/टुकड़े

लिक्विड स्क्रीन सेपरेटर उत्पाद की विशेषताएं

- Electric

- Stainless Steel

- 1440 RPM

- Easy to clean, High separation efficiency, Low vibration

- 0.5 to 2 HP

- Polished

लिक्विड स्क्रीन सेपरेटर व्यापार सूचना

- प्रति दिन

- दिन

उत्पाद वर्णन

Liquid Screen Separator

We have expertise in manufacturing & supplying an exclusive range of liquid screen separators which are highly effective for separating solid particles from liquids. These are high speed vibrating type liquid separators which remove the solids which enhance the filtration capacity and efficiency of the filters. These separators are widely used in several mill plants to remove the solid particles.

Superior Separation Technology

Built for optimal performance, the vertical screen separator uses advanced screening mechanisms to efficiently separate solids from liquids. The stainless steel construction ensures longevity and high resistance to corrosion, even in demanding environments.

Designed for Ease and Reliability

With its easy-to-clean polished surface and low-vibration design, this separator ensures minimal maintenance and a safer workplace. The vertical structure takes up less floor space, making it an ideal choice for tighter manufacturing layouts.

Powerful Yet Efficient Operation

Powered by a robust 0.5 to 2 HP electric motor, the machine achieves consistent speeds of 1440 RPM. This setup guarantees efficient throughput while keeping energy consumption and operational noise to a minimum.

FAQs of Liquid Screen Separator:

Q: How does the liquid screen separator operate without conveyors?

A: This screen separator utilizes a vertical structure and specialized screens to separate solids from liquids directly. Without belt, roller, or pneumatic conveyors, materials are processed as they enter the screening area, resulting in streamlined operation and reduced maintenance complexity.Q: What materials is the separator made of, and why is this important?

A: The separator is constructed from polished stainless steel, providing excellent corrosion resistance and an easy-to-clean surface. This choice of material ensures durability and sanitary operation, particularly important in food, pharmaceutical, and chemical processing industries.Q: When should I use this vertical liquid screen separator?

A: This equipment is best employed when there is a need for high-efficiency liquid-solid separation, especially in environments where corrosion resistance and easy cleaning are priorities. Its particularly suitable for continuous manufacturing processes requiring reliable performance.Q: Where can this separator be installed within a processing facility?

A: Thanks to its vertical design and compact footprint, the separator can be installed in areas with limited space, either as a stand-alone unit or as part of an integrated processing line.Q: What is the process of cleaning the separator?

A: Cleaning is straightforward due to the polished stainless steel finish. Operators only need to disassemble the screen components as per manufacturers guidance and rinse the surfaces with appropriate cleaning agents to maintain hygiene.Q: How does the separator ensure high separation efficiency?

A: At 1440 RPM and with optimized screen design, the separator effectively sorts solids from liquids in continuous flow. The vertical structure minimizes material buildup, ensuring consistent and efficient operation throughout each cycle.Q: What benefits does this screen separator offer over other types?

A: This separator stands out for its corrosion-resistant stainless steel build, easy cleaning process, low vibration, and high separation efficiency. By eliminating conveyor components, it offers simpler operation, reduced maintenance, and enhanced longevity for industrial applications.Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email